The CP4 Pump: Your Diesel Engine's Ticking Time Bomb?

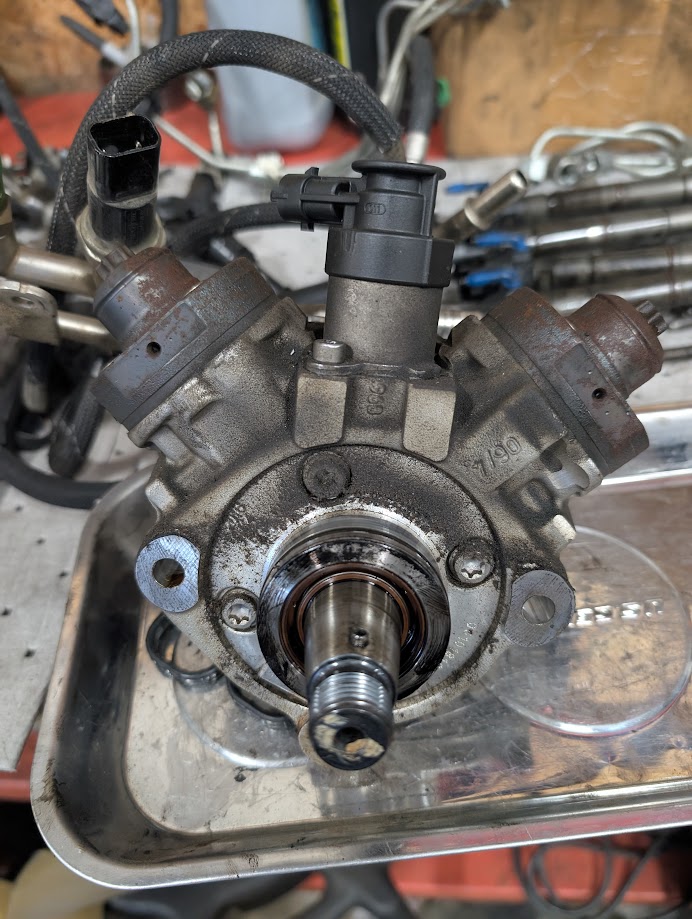

The heart of your modern diesel truck is its high-pressure fuel injection system, and for many years, the Bosch CP4 pump was at the center of it all. Found in popular trucks from Ford, GM, and Ram, the CP4 was designed for efficiency. However, it has earned a notorious reputation for premature and catastrophic failure. Understanding why this happens and what you can do about it is crucial for any diesel owner.

At Rochas Automotive, we've seen firsthand the damage a failed CP4 pump can cause. This guide will walk you through how the CP4 works, why it fails, and the practical steps you can take to protect your investment.

What is a CP4 Injection Pump and How Does It Work?

The CP4 high-pressure fuel pump has a critical job: it takes low-pressure fuel from the tank and pressurizes it to incredibly high levels (often over 30,000 PSI). This highly pressurized fuel is then delivered to the injectors, which spray a fine mist into the engine's cylinders for combustion.

Unlike its more robust predecessor, the CP3, the CP4 uses a different design to generate this pressure. It features two small, opposing pistons that are moved by a camshaft. This design is more compact and theoretically more efficient. However, this efficiency comes at the cost of durability, especially when conditions aren't perfect.

The Achilles' Heel: Why CP4 Pumps Fail

The primary reason CP4 pumps are prone to failure lies in their design and sensitivity to fuel quality. The internal components, particularly the roller lifters and camshaft, have very tight tolerances and rely entirely on the diesel fuel itself for lubrication. When that lubrication is compromised, things go wrong quickly.

Here are the most common causes of CP4 failure:

1. Fuel Contamination

This is the number one enemy of the CP4 pump. Even small amounts of water, dirt, or debris in the fuel can disrupt the thin lubricating film between the metal components.

- Water Contamination: Water has zero lubricating properties. When it enters the pump, it causes immediate metal-on-metal contact, leading to rapid wear and scoring of the pistons and camshaft. Water also promotes corrosion.

- Debris: Dirt and other particles act like sandpaper inside the pump, grinding away at precision-machined surfaces.

2. Air in the Fuel System (Aeration)

If air gets into the fuel lines—perhaps from running the tank too low or a leak in the system—it creates air pockets. These pockets interrupt the fuel's lubricating film, causing the pistons to hammer against the camshaft without a protective cushion. This process, known as cavitation, quickly destroys the pump's internals.

3. Poor Fuel Lubricity

Modern Ultra-Low Sulfur Diesel (ULSD) has significantly less sulfur than older diesel formulas. While this is great for the environment, sulfur is a natural lubricant. The process of removing it reduces the fuel's natural ability to lubricate. The CP4 pump, with its high-friction design, is particularly vulnerable to the effects of poor lubricity, leading to accelerated wear over time.

The Catastrophic Result of Failure

A CP4 failure isn't just a minor inconvenience; it's a catastrophic event for your entire fuel system. When the pump's internal components begin to break down, they shed tiny metal particles, often referred to as "glitter."

This metal debris is then sent at high pressure throughout the fuel system. It contaminates everything in its path:

- Fuel rails

- Pressure regulators

- Fuel lines

- All of your expensive fuel injectors

The result is a repair bill that can easily climb into the thousands, as the entire fuel system often needs to be replaced—from the tank to the injectors. Simply replacing the failed pump is not enough, as the residual metal will destroy the new pump in short order.

How to Prevent CP4 Pump Failure: Your Action Plan

While the CP4's design has inherent weaknesses, you are not powerless. Proactive maintenance can significantly reduce your risk of a catastrophic failure.

1. Install a Lift Pump

A high-quality aftermarket lift pump is arguably the single best investment you can make for your CP4-equipped truck. A lift pump provides a steady, positive supply of fuel from the tank to the injection pump. This ensures the CP4 is never starved for fuel, eliminating the risk of air entering the system. Many lift pumps also offer vastly superior fuel filtration and water separation compared to the factory setup, providing an extra layer of defense against contamination.

2. Prioritize Fuel Filter Maintenance

Your fuel filters are your first line of defense. Never skip or extend the manufacturer's recommended service intervals. Use only high-quality, OEM-spec filters. Cheaper, lower-quality filters may not effectively remove water or the fine particulates that can damage the pump. At Rochas Automotive, we can advise you on the best filters for your specific truck and driving conditions.

3. Use a High-Quality Fuel Additive

A good diesel fuel additive addresses two key weaknesses: lubricity and water. Choose an additive that is specifically formulated to increase the lubricity of ULSD fuel. Many top-tier additives also include a demulsifier, which helps separate water from the fuel so it can be captured by your water separator. Regular use of a quality additive is cheap insurance against a major repair.

4. Avoid Running Your Tank Low

Make it a habit to refuel when your tank reaches the quarter-full mark. Running the tank close to empty increases the risk of sucking up sediment or water that has settled at the bottom. It also puts more strain on the fuel system, increasing the chance of pulling air into the lines, especially on inclines or during hard acceleration.

Considering Pump Conversion Options: CP3 and DCR

If you own a Duramax-powered truck, a CP3 conversion kit is an excellent choice for long-term reliability. This upgrade replaces the problematic CP4 pump with the older, much more robust CP3 unit. The CP3 was designed to handle higher loads and is far less susceptible to issues caused by poor fuel quality or lubrication. While the conversion is more involved and can be costly upfront, it effectively addresses the core weaknesses of the CP4 and provides peace of mind for Duramax owners.

For Ford 6.7L Power Stroke owners, the CP3 conversion is not compatible. Instead, the DCR (Diesel Common Rail) pump conversion is the recommended solution. The DCR pump is specifically engineered to fit the Ford 6.7L platform, offering greatly improved durability and reliability over the factory CP4. It addresses many of the same vulnerabilities—such as improved lubrication, resistance to fuel quality issues, and drastically reduced risk of catastrophic failure. Upgrading to a DCR pump is an excellent preventative measure to help ensure the longevity of your Ford 6.7L diesel engine.

Trust Rochas Automotive with Your Diesel Engine

Navigating the complexities of modern diesel engines can be challenging, but you don't have to do it alone. The expert technicians at Rochas Automotive specialize in diesel performance, maintenance, and repair. We have the knowledge and tools to diagnose issues with your fuel system, recommend the right preventative measures, and perform high-quality repairs you can count on.

Whether you need a routine fuel filter service, want to discuss installing a lift pump, or are considering a full CP3 conversion, we are here to help protect your truck for the long haul.

Don't wait for a small problem to become a catastrophe. Schedule your diesel service with Rochas Automotive today and drive with confidence.